The shipping industry’s compliance with the IMO 2020 sulfur cap necessitated a widespread shift to lower-sulfur fuels, primarily Very Low Sulfur Fuel Oil (VLSFO) (max 0.50% sulfur) and Ultra Low Sulfur Fuel Oil (ULSFO) (max 0.10% sulfur). While this transition is crucial for environmental protection, it introduces a new set of operational challenges and requirements for modern marine engines.

Characteristics of Low-Sulfur Fuels

Advantages of Low-Sulfur Fuels

The primary drive for adopting VLSFO and ULSFO is environmental regulation, but these fuels also offer some operational benefits:

- Environmental Compliance: The main advantage is meeting the stringent IMO regulations, significantly reducing Sulfur Oxide (SOx) emissions, which are harmful to human health and contribute to acid rain.

- Reduced Engine Contamination (for ULSFO): Fuels with extremely low sulfur content (like MGO/MDO used as ULSFO) generally lead to lower deposit formation in the combustion space, requiring less frequent cleaning.

- Less Corrosive Exhaust Gases: Lower sulfur content results in less formation of sulfuric acid in the exhaust gas systems, which can extend the lifespan of components like exhaust valves and turbochargers.

- Lower Piston Crown Temperatures (for MGO/MDO type ULSFO): Distillate fuels generally have better combustion properties, which can lead to slightly cooler running conditions compared to heavy fuel oil.

Disadvantages and Operational Challenges

The new fuel formulations, especially VLSFO, which is a blend, bring unique challenges that can directly impact engine performance and maintenance:

- Viscosity and Cold Flow Issues: VLSFO blends can exhibit poor stability and compatibility. Inconsistent viscosity and issues with the fuel’s cold flow properties (wax precipitation) can lead to problems with fuel transfer, purification, and injection, especially in colder climates or during extended storage.

- Reduced Lubricity: Low-sulfur fuels often have lower inherent lubricity compared to traditional Heavy Fuel Oil (HFO). This is a critical issue for high-pressure components like fuel pumps and injectors, increasing wear rates.

- Increased Risk of Catastrophic Wear (Scuffing): The chemical makeup of new fuels, combined with the need to use new low-base number (BN) cylinder oils, can increase the risk of severe abrasive wear, particularly cylinder liner scuffing and piston ring seizure.

- Sludge Formation and Fouling: Poorly blended or incompatible VLSFO batches can result in accelerated sludge formation and sediment deposition, leading to filter blockages, purifier overload, and fuel system fouling.

- Fuel Management Complexity: Crews must manage multiple fuel types (HFO, VLSFO, MGO/MDO) and carefully handle the changeover process, requiring complex tank management and heating procedures to prevent compatibility issues.

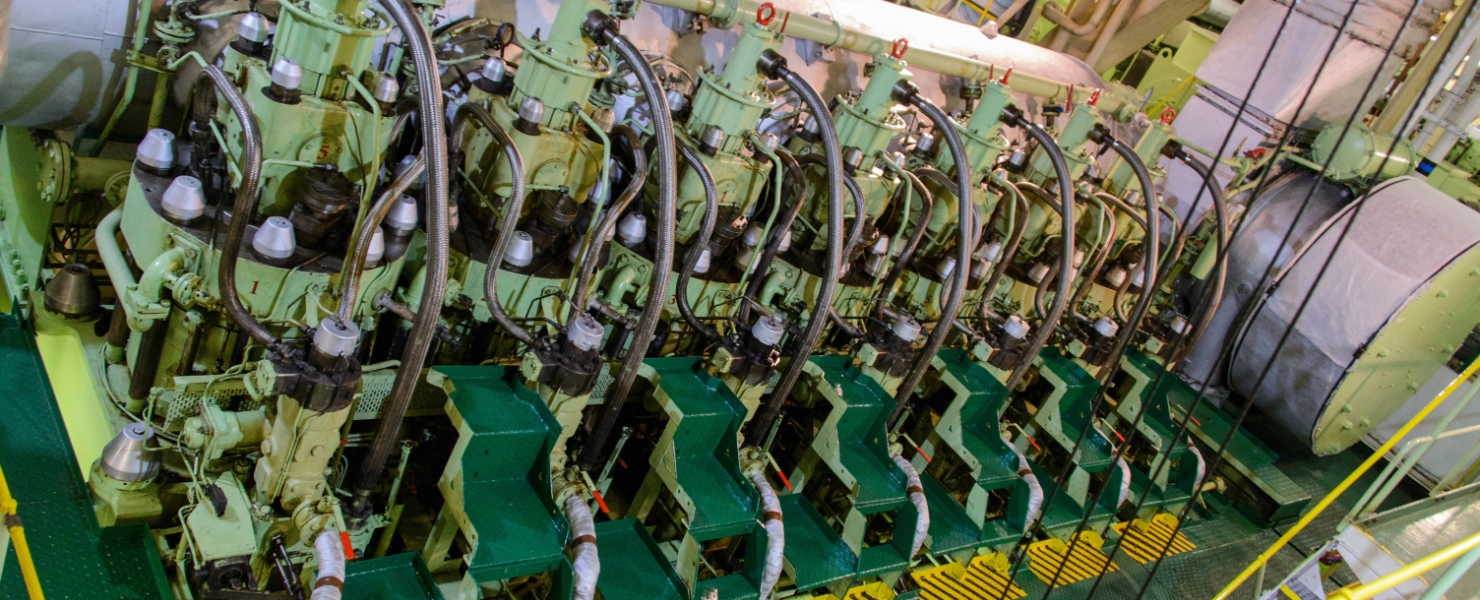

Impact on Marine Engine Components

The operational characteristics of low-sulfur fuels directly influence the wear and tear on various critical engine parts.

1. Piston Rings and Cylinder Liners

This is arguably the most affected area. The combination of low-sulfur fuels and the required switch to low-BN cylinder lubricating oils (to prevent bore polishing and excess deposits) creates a delicate balance:

- Scuffing Risk: Low lubricity and inadequate acid neutralization from low-BN oils increase the potential for the protective oil film to break down. This leads to direct metal-to-metal contact, causing scuffing and seizure of the piston rings and cylinder liners.

- Increased Wear: Despite the low sulfur, improper lubrication can accelerate general wear, particularly on the contact surface between the piston ring and the liner.

- Solution Focus: This is precisely why Ceramic Metal Piston Rings (Cermet) are becoming essential. Their composite material offers superior wear and seizure resistance, mitigating the scuffing risks associated with these new fuels.

2. Fuel Injection Equipment (Pumps and Injectors)

The parts responsible for pressurizing and injecting fuel are highly susceptible to changes in fuel quality:

- Increased Wear due to Poor Lubricity: Components such as plungers and barrels in fuel pumps, which rely on the fuel itself for lubrication, experience accelerated wear due to the lower lubricity of VLSFO/ULSFO.

- Nozzle Fouling: Poor combustion and the presence of non-combustible materials in VLSFO can lead to the formation of deposits on the injector nozzles, impairing the spray pattern and leading to inefficient combustion.

3. Filters and Purifiers

The stability and cleanliness of the fuel significantly affect the pre-combustion handling equipment:

- Filter Blockages: Incompatible VLSFO blends are prone to asphaltene precipitation, forming heavy sludge that rapidly blocks filters and can overwhelm centrifugal purifiers.

- Thermal Stress: To maintain the correct viscosity for injection and purification, VLSFO must be heated precisely. Incorrect heating can further destabilize the fuel, leading to more sludge.

Navigating the transition to VLSFO and ULSFO requires a strategic approach to fuel management and engine component selection. While these fuels are vital for environmental compliance, their inconsistent properties demand greater vigilance, especially regarding lubrication and wear protection.

To protect critical components like cylinder liners from the increased risk of scuffing and seizure in this new fuel environment, advanced solutions are necessary.

To learn how modern engine components are engineered to withstand the challenges posed by VLSFO/ULSFO, read our detailed guide on Ceramic Metal Piston Rings: Your Guide to Engine Protection with Low-Sulfur Fuels.